17 chromium and 4 nickel.

17 4 stainless steel vs 316.

17 4 ph vs 316 offer high corrosion resistance.

One distinguishing factor are the 17 4 ph shafts.

When you compare stainless steel 17 4 ph vs 316 it is obvious that 17 4 ph has higher hardening content.

Almost at any condition the corrosion resistance for 316 is better than 17 4.

This article will focus on two types in particular.

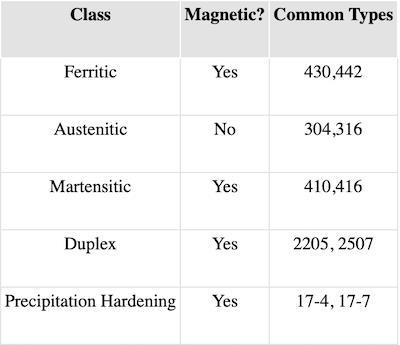

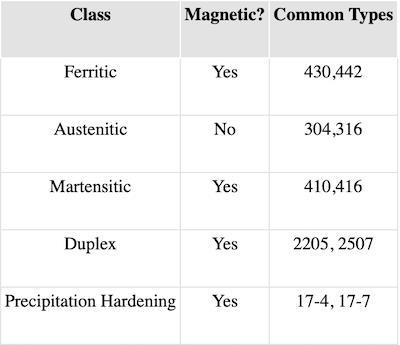

Precipitation hardening grade is a combination of two stainless steel structures i e.

But it isn t 316 and you re not quite sure why that matters but you have a piece of paper in front of you that says it does so go on and elaborate.

The numbers 17 4 refer to its composition.

Ss316 and 17 4 ph are common used two types of stainless steel grades for investment casting.

The 17 4 ph stainless steel is magnetic and less corrosion resistant than 316l stainless steel.

17 4 stainless steel also known as sae type 630 is a common and exceptionally durable type of steel used in a diverse variety of industries and applications.

17 4 ph steel has been chosen by waukesha and copied by others because of the extended service it offers under extreme conditions.

Standard 316l is slightly magnetic but non magnetic versions are available.

316 is typical austenite stainless steel casting grade while 17 4 ph stainless steel is precipitation hardening material grade which are all defined in american standards.